Rubber vulcanizing Tester commercial|ASTM D412 Tension Testing Rubber & Elastomers : department Store This video is to show the introduce of Demo video of SKZ131 Rubber vulcanizing Tester, kindly check and hope helpful, if there is any questions, kindly contact us: email:. 17 de fev. de 2024 · O saque do Betfair pode levar até cinco dias úteis para ser concluído, mas é mais comum receber os seus ganhos bem antes. O saque por Pix na Betfair, por .

{plog:ftitle_list}

webWe are RVA — a software outsourcing company that develops applications and services, blockchain solutions and electronic payment systems. Our main resource is a strong .

custom moisture meter for hay

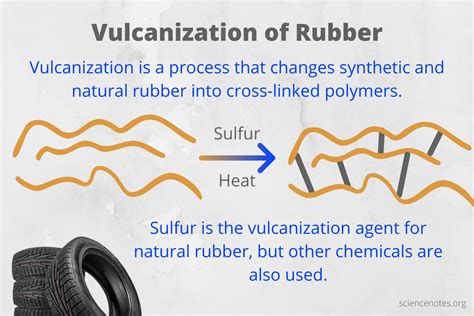

Vulcanization of Rubber

Proper tensile testing of vulcanized (durable) rubber and thermoplastic elastomers per ASTM D412 is quite useful since these compounds are one of the most complex and universally used .1 2. The ASTM D412 tensile test for rubber and elastomers is a standard test that was designed to provide a way of evaluating the performance of rubber and elastomeric materials. The test . This video is to show the introduce of Demo video of SKZ131 Rubber vulcanizing Tester, kindly check and hope helpful, if there is any questions, kindly contact us: email:.

Standard Test Methods for Vulcanized Rubber and Thermoplastic

Testing standard descriptions and compatible instruments conforming to the specifications of many standards organizations such as ASTM, DIN, and ISO and many test types, such as vulcanization, hardness, density, and Mooney .

This test method covers the use of the oscillating disk cure meter for determining selected vulcanization characteristics of vulcanizable rubber compounds. 1.1 These test methods cover procedures used to evaluate the tensile (tension) properties of vulcanized thermoset rubbers and thermoplastic elastomers. These methods .

1.1 These test methods cover procedures used to evaluate the tensile (tension) properties of vulcanized thermoset rubbers and thermoplastic elastomers. These methods are not appli .Making Rubber Stronger Through Vulcanization. Rubber is a polymer of isoprene that is formed with double bonds between each of the individual monomers (or units). In simple terms, one of these bonds is flexible and can allow the polymer to take up many shapes and sizes, which is what basically gives rubber its property of elasticity.

Standard Vulcanized Sheets D3183 Practice for Rubber—Preparation of Pieces for Test Purposes from Products D3767 Practice for Rubber—Measurement of Dimensions D4483 Practice for Evaluating Precision for Test Method Standards in the Rubber and Carbon Black Manufacturing Industries E4 Practices for Force Verification of Testing Machines 2.2 .ISO 1853, Conducting and dissipative rubbers, vulcanized or thermoplastic — Measurement of resistivity [2] ISO 2878, Rubber, vulcanized or thermoplastic — Antistatic and conductive products — Determination of electrical resistance [3] In naming this process, he chose to call his discovery vulcanization, after the Roman god of fire: Vulcan. Today, rubber comes both naturally from the rubber tree and from artificial sources. Vulcanization remains crucial for making rubber stronger, and vulcanized rubber is often the type of the material in contact with the average person. Vulcanization of the rubber phase occurs as mixing continues. After removal from the mixer, the cooled blend can be chopped, extruded, pelletized, injec- tion molded, etc. Such a composition is described as a dispersion of very small particles of vulcanized rubber in a thermoplastic resin matrix.

Vulcanization. A.Y. Coran, in The Science and Technology of Rubber (Fourth Edition), 2013 Abstract. The vulcanization process is necessary to produce most useful rubber articles, like tires and mechanical goods. This chapter is an overview of the science and technology of vulcanization. Emphasis is placed on general-purpose “high-diene” rubbers like natural .Industrial autoclaves are specialized containers designed to sterilize, cure, or strengthen objects using high temperatures and pressure. They are used for a variety of applications, from sterilizing medical equipment to curing composite components, . Vulcanized rubber is tougher and less likely to decompose than natural rubber, but there is evidence that vulcanized rubber will biodegrade in hot composting bins. The benefit of vulcanization is that rubber products can easily be refurbished or .Vulcanization is a process generally applied to rubbery or elastomeric materials. These materials forcibly retract to their approximately original shape after a rather large mechanically imposed deformation. Vulcanization can be defined as a process that increases the retractile force and reduces the amount of permanent deformation remaining after removal of the deforming force.

JP0050691 JAERI-Conf 2000^003 5. Progress in Radiation Vulcanization of Natural Rubber Latex K. MAKUUCHI Takasaki Radiation Chemistry Research Establishment, JAERI 1233 Watanuki, Takasaki Gunma, 370-12 Japan 1. Natural rubber (NR) is a polymer obtained from renewable sources and presents a wide variety of applications ranging from simple household objects to high technological products [].The various applications of this raw material are dependent on the vulcanization process, which provides the desired mechanical properties to the rubber objects, such as elasticity, .METHODS OF TEST FOR VULCANIZED RUBBER PART 1 DETERMINATION OF TENSILE STRESS-STRAIN PROPERTIES ( Third Revision ) IS 3400 (Part 1) : 2012 ISO 37 : 2011 1. 3.2 elongation E tensile strain, expressed as a percentage of the test length, produced in the test piece by a tensile stress 3.3Although the improvement in the properties of natural rubber (NR) brought about by vulcanization with sulfur was discovered by Goodyear and by Hancock 130 years ago and the process has since become the basis of a world-wide commercial manufacturing industry, a scientific understanding of the changes taking place has begun to emerge only in the last 30 .

Mooney Viscosity. The Mooney Viscosity test is a well-established method for characterizing uncured rubber materials. Following well- defined standard procedures, the sample is preheated for a defined period, then sheared at a constant rate.The Mooney Viscosity is recorded from the end of this deformation stage. in the present example, the outstanding precision of the MVone .

Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension D0412-16R21 ASTM|D0412-16R21|en-US Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension Standard D412 Standard Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension> new BOS Vol. .addition of vulcanizing agents along the polymer chains to enable the strength and elastic properties inherent in raw rubber to be fully realized [1]. This is achieved when the compounded rubber is heated to an appropriate temperature. The first commercial method of cross linking has been attributed to Charles Goodyear in 1839 [2]

Learn about Rubber compounding: https://youtu.be/yK6-QNB1roo?si=jzlrsKFDhkssuCTpThis video explains the basics of the rubber vulcanization process, including. Studies on the mobility of ions in an electric field, together with the theory of radiation and ionization, have contributed to the creation of the first commercial analytical instrument in this field - plasma chromatograph (PC) [1].Over its approximately 50 years of existence, ion mobility spectrometer (IMS), which is a highly developed apparatus, has gained . 7.1.4 Other test specimen sizes may be used as dictated by end use. 7.2 The Þrst three test specimens described above were evaluated in interlaboratory testing. The washer type test specimen ( 7.1.3 ) is preferred. 7.3 Preparation of Test SpecimensÑ Test specimens may be prepared by taking a sample of the compound or material of interest.Potential employees can watch to find out what kind of work environment Custom Rubber offers and see the type of work. Custom Rubber Corp. is now hiring, .85 starting wage for night shift. Read More; Custom Rubber Corp. article in Inside Rubber Magazine. Custom Rubber Corp. was featured in an article in the most recent Inside Rubber Magazine .

5.1 This test method is used to determine the vulcanization characteristics of (vulcanizable) rubber compounds. 5.2 This test method may be used for quality control in rubber manufacturing processes, for research and development testing of raw-rubber compounded in an evaluation formula-tion, and for evaluating various raw materials used in .In this chapter we will direct out attention to the test procedures and instruments used to measure two of the most critical properties of rubber and rubber compounds, processibility and vulcanization.These characteristics are vitally important because they define the operating window available for converting uncured rubber compound into a usable product.

Standard Test Methods for Vulcanized Rubber and

The story and science behind one of the most important developments in polymer science. How is vulcanized rubber made? Why is it important? In what applicati.

SKZ131 Rubber vulcanizing Tester

D2084 Test Method for Rubber Property—Vulcanization Using Oscillating Disk Cure Meter D5289 Test Method for Rubber Property—Vulcanization . 4.1.1 The materials required for standard rubber test formu-las shall be Industry Reference Materials (IRM) as specified in Specification D5900. The current list of Industry Reference An international standard, ISO 2921:2019 – Rubber, Vulcanized – Determination Of Low-Temperature Characteristics – Temperature-Retraction Procedure (TR Test), helps test vulcanized rubber. Vulcan is the Roman god of fire, metalworking, and the forge. He’s even where we get the word “volcano”— the Italian volcano derives from the Latin Vulcanus.vulcanization of rubber test mixes specified in the various International Standards for the evaluation of such test mixes. 2 Normative references The following documents, in whole or in part, are normatively referenced in this document and are indispensable for its application. For dated references, only the edition cited applies.

A unique ultrafine full-vulcanized powdered ethyl acrylate rubber (EA-UFPR) was used as the toughening modifier for poly (lactic acid) (PLA). Largely improved tensile toughness was successfully achieved with the incorporation of only 1 wt% EA-UFPR, while the tensile strength and modulus of the blends were almost the same as pure PLA.

custom moisture meter near me

custom moisture wood meter

O Microsoft 365, anteriormente Office 365, abrange planos d.

Rubber vulcanizing Tester commercial|ASTM D412 Tension Testing Rubber & Elastomers